1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

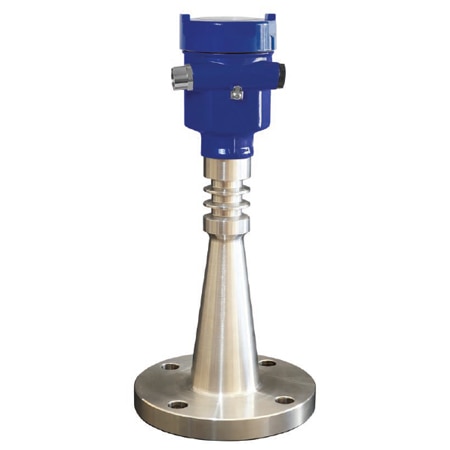

LR20-Series

Flowline Flange Mount Radar Level Transmitter (up to 65.6ft)

Models In Stock

- 316L antenna with PTFE inner shield for corrosive media

- Simple configuration via integral push button display module

- 26 GHz. pulse radar is unaffected by vapor or condensation

- 12” (30cm) dead band enables utilization of the entire tank

LR20-Series

From

$

3,248.53

Models In Stock

Product Overview

- Accuracy ± 3 mm

- Antenna Diameter 7.5 in

- Antenna Length 6.5 in

- Approvals CE, RoHS, CRN, cTUVus, FCC

- Bar Graph Percent of Span

- Beam Angle 12°

- Configuration Push Button

- Deadband 12 in

- Display and Indications Echo Signal Curve

- Display Measuring Units ft, m

- Display Type LCD

- Electrical Connection 1/2 in NPT

- Electrical Output 4 to 20 mA

- Enclosure Ratings IP67, NEMA Type 6

- Flange Thickness 0.88 in

- Frequency 26 GHz

- Materials 316 Stainless Steel, Polycarbonate, Aluminum

- Measuring Range, Min 1 ft

- Memory Non-Volatile

- Number of Wires 2

- Operating Pressure, Max 72 psi

- Operating Pressure, Min -14.5 psi

- Power Consumption 22.5 mA

- Probe Type 3" Antenna

- Process Connection Size 3 in

- Process Connection Type ANSI Flange

- Process Temperature, Max 150 °C

- Process Temperature, Min -40 °C

- Signal fail-safe 3.9 mA, 20.5 mA, 22 mA

- Signal invert 4 to 20 mA, 20 to 4 mA

- Storage Temperature, Max 80 °C

- Storage Temperature, Min -40 °C

- Supply Voltage 16 to 26 Vdc

- Tank Type Any

- Temperature Compensation Automatic

The general purpose 26 GHz. pulse radar transmitter provides continuous level measurement up to 65.6’ (20m) with a 4-20 mA signal output, and is configured via its integral push button display module. The non-contact liquid level sensor is intended for chemical storage or process applications in above or below grade tanks of any material. Select this sensor for challenging process conditions with corrosive media, light surface foam or agitation, higher temperature or pressure, condensation or vapor, and installation in a flange fitting. Typical applications include bulk storage and process tanks.

PDFs & Manuals