1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

LVU700-Series

Reflective Ultrasonic Level Transmitter for Large Tanks

Models In Stock

- Ultrasonic Liquid Level Transmitter with Reflective Technology™ measures reliably with condensation

- Offered in 6m (19.6’) and 12m (39.3’) measurement ranges

- Corrosion resistant PVDF transducer with IP68 PP enclosure

- Fail-safe diagnostics with selectable signal fail-safe outputs

LVU700-Series

From

$

932.56

Models In Stock

Product Overview

- Accuracy ± 0.2 %

- Approvals ul61010_1

- Compliance CE, RoHS 2

- Conduit Entrance 1/2 in NPT female

- Configuration Push button or WebCal® PC Windows® USB® 2.0

- Display lcd

- Display Measuring Units cm, in, %

- Electrical Output 4 to 20 mA

- Enclosure Ratings IP68, NEMA 6 to 30P for 240V

- Loop Resistance 500 Ω @ 24 Vdc

- Media Compatibility Alkaline solutions, Dilute Acids, Hydraulic Oil, Light Oil, Oil, Solvents, Water, Water-based fluids

- Memory Non - Volatile

- Number of Digits 6

- Number of Wires 2

- Operating Pressure, Max 30 psi

- Operating Temperature, Max 60 °C

- Operating Temperature, Min -35 °C

- Output Signal Current

- Process Temperature, Max 80 °C

- Process Temperature, Min -40 °C

- Signal fail-safe 4 mA, 20 mA, 21 mA, 22 mA or hold last

- Signal invert 4 to 20 mA or 20 to 4 mA

- Temperature Compensation Automatic

- Transducer Type Reflective Ultrasonic

The LVU700 Series general purpose reflective ultrasonic level transmitter provides continuous level measurement up to 39.3’ (12m) with a 4-20 mA analog signal output and is configured via its integral push button display module or LVCN414-SW software. The non-contact liquid level sensor features our proprietary Reflective Technology that delivers reliable level measurement in condensing environments. Select this sensor for bulk tanks with chemicals, water, wastewater and oil (non-foaming and/or highly vaporous liquids). Typical applications include bulk storage, neutralization tank, clarifier and waste sumps.

Applications: Bulk storage, neutralization tanks, clarifier and waste sumps

Configuration: In addition to the push button display module, the sensor may be configured via our LVCN414-SW software and one Fob USB adapter. LVCN414-SW is a PC utility program that allows users to easily configure their sensors, update firmware, save configurations and print wiring schematics prior to installation. LVCN414-SW is a free download from our website.

Fob USB Adapter LVU500-USB for programming LVU500 or LVU700 Series Level Transmitters.

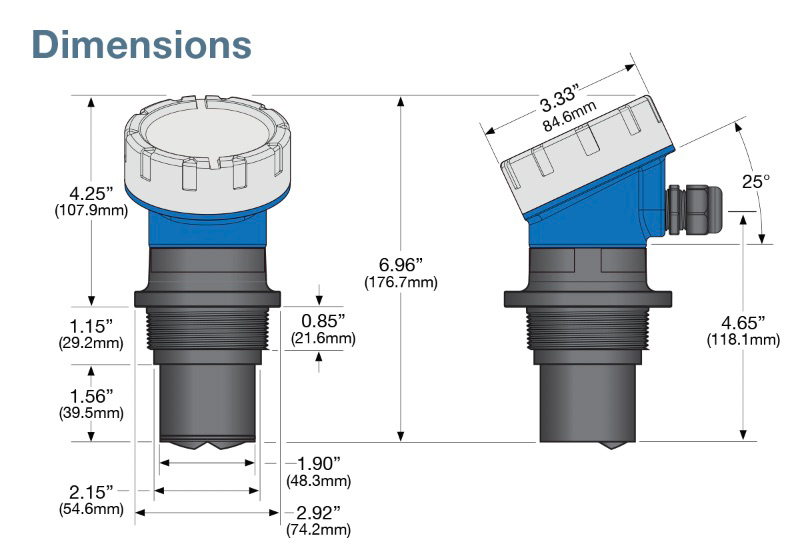

Dimensions for LVU712 Series

Specifications:

Range: LVU706: 8” to 19.6’ (20cm to 6m), LVU712: 18” to 39.3’ (45.7cm to 12m)

Accuracy: ± 0.2% of range

Resolution: LVU706: 0.079” (2mm), LVU712: 0.196” (5mm)

Deadband: LVU706: 8” (20.3cm) , LVU712: 18” (45.7cm)

Beam width: LUV706: 3” (7.6cm), LUV712: 6” (15.2cm)

Configuration: Push button or WebCal® PC Windows® USB® 2.0

Memory: Non-volatile

Display: LCD, 6-digit

Display units: Inch, cm, or percent

Supply voltage: 14-28 VDC

Max. consumption: 0.5W

Loop resistance: 500 ohms @ 24 VDC

Signal output: 4-20 mA, two-wire

Signal invert: 4-20 mA or 20-4 mA

Signal fail-safe: 4 mA, 20 mA, 21 mA, 22 mA, hold last

Process temp.: -40 to 176ºF, (-40 to 80ºC)

Temp. comp.: Automatic

Ambient temp.: -31 to 140ºF, (-35 to 60ºC)

Pressure: 30 psi (2 bar)

Enclosure rating: Type 6P (IP68)

Encl. material: Polypropylene

Encl. cap material: Clear polypropylene

Enclosure vent: Water tight membrane

Conduit entrance: ½” NPT

Transducer type: Reflective Ultrasonic

Transducer mat.: Polyvinylidene fluoride

Process mount: 2” NPT, or 2” G

Mount gasket: 2” NPT: N/A, 2” G: Viton®

Classification: General purpose

Approval: UL 61010-1

Compliance: CE, RoHS

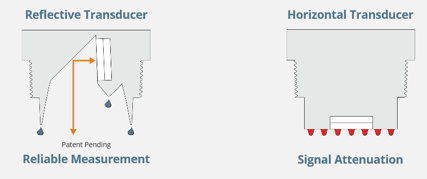

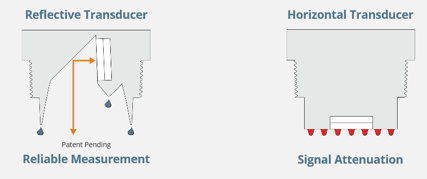

Reflective Technology

Condensation is the most common issue for ultrasonic level transmitters. Condensation attenuates the acoustic signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise ratio by up to 50%, and substantially reducing their measurement reliability. At the core of Reflective Technology is a simple fact. Unlike flat horizontal surfaces, significant water droplets cannot adhere to smooth vertical surfaces. By orienting the transducer vertically, condensation runs off the transducer and does not affect sensor performance. The unimpeded transmit and receive signals are redirected to and from the liquid off a 45º reflector, delivering reliable level measurement.

Applications: Bulk storage, neutralization tanks, clarifier and waste sumps

Configuration: In addition to the push button display module, the sensor may be configured via our LVCN414-SW software and one Fob USB adapter. LVCN414-SW is a PC utility program that allows users to easily configure their sensors, update firmware, save configurations and print wiring schematics prior to installation. LVCN414-SW is a free download from our website.

Fob USB Adapter LVU500-USB for programming LVU500 or LVU700 Series Level Transmitters.

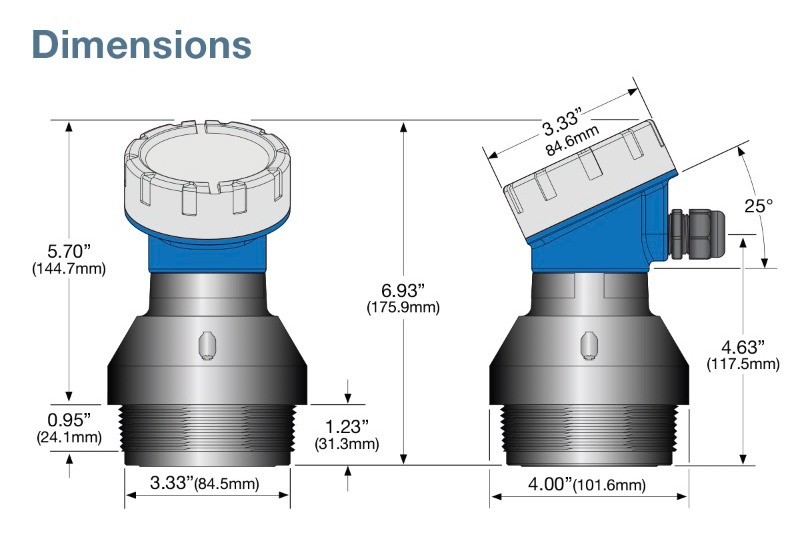

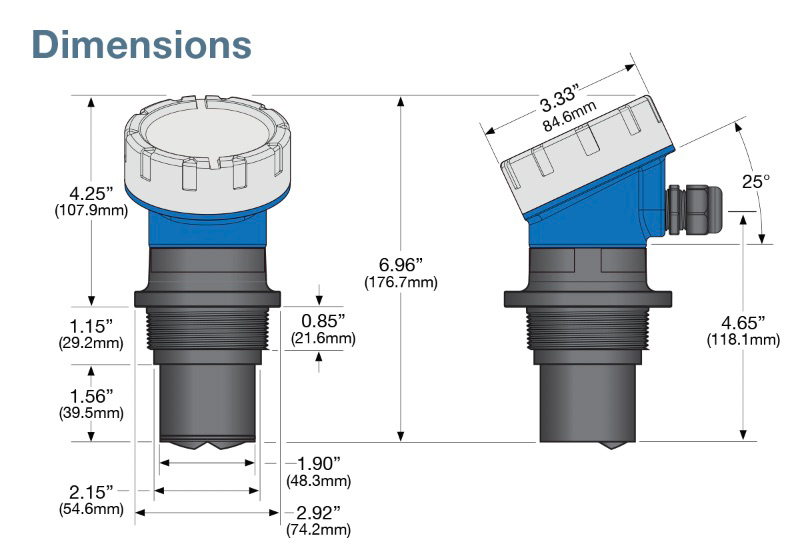

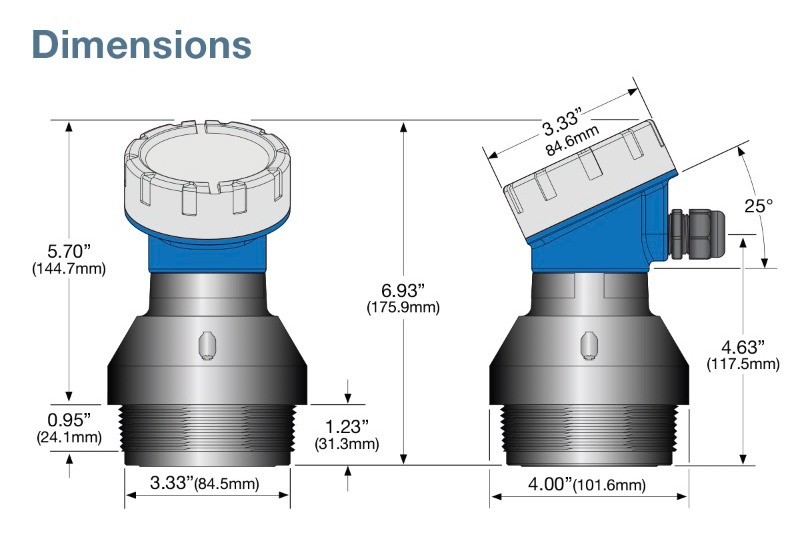

Dimensions

Dimensions for LVU706 Series

Dimensions for LVU712 Series

Specifications:

Range: LVU706: 8” to 19.6’ (20cm to 6m), LVU712: 18” to 39.3’ (45.7cm to 12m)

Accuracy: ± 0.2% of range

Resolution: LVU706: 0.079” (2mm), LVU712: 0.196” (5mm)

Deadband: LVU706: 8” (20.3cm) , LVU712: 18” (45.7cm)

Beam width: LUV706: 3” (7.6cm), LUV712: 6” (15.2cm)

Configuration: Push button or WebCal® PC Windows® USB® 2.0

Memory: Non-volatile

Display: LCD, 6-digit

Display units: Inch, cm, or percent

Supply voltage: 14-28 VDC

Max. consumption: 0.5W

Loop resistance: 500 ohms @ 24 VDC

Signal output: 4-20 mA, two-wire

Signal invert: 4-20 mA or 20-4 mA

Signal fail-safe: 4 mA, 20 mA, 21 mA, 22 mA, hold last

Process temp.: -40 to 176ºF, (-40 to 80ºC)

Temp. comp.: Automatic

Ambient temp.: -31 to 140ºF, (-35 to 60ºC)

Pressure: 30 psi (2 bar)

Enclosure rating: Type 6P (IP68)

Encl. material: Polypropylene

Encl. cap material: Clear polypropylene

Enclosure vent: Water tight membrane

Conduit entrance: ½” NPT

Transducer type: Reflective Ultrasonic

Transducer mat.: Polyvinylidene fluoride

Process mount: 2” NPT, or 2” G

Mount gasket: 2” NPT: N/A, 2” G: Viton®

Classification: General purpose

Approval: UL 61010-1

Compliance: CE, RoHS

PDFs & Manuals

Software & Drivers

Accessories

Show Ratings & Reviews

Can this be mounted horizontally or vertically? Or does it need to be one way?

Thank you for your inquiry about the reflective level sensor. It mounts in the vertical positin where the beam points down into the tank towards the liquid.

Date published: 2024-02-16

Can you let me know if this sensor is compatible with HART communications?

Thank you for your inquiry. This level sensor outputs a 4 to 20 mA output and if the HART protocol accepts this signal, then, yes.

Date published: 2024-11-21

I see there's a beam width of 6" for the LVU712 model. Is there a beam angle as well?

Thank you for your inquiry for this level sensor. It is a beam width, no angle.

Date published: 2020-08-21

Hello, I was wondering if this sensor has to be recalibrated or replaced after a certain amount of time?

Thank you for your inquiry! There is no set timeline for re-calibration or replacement of these ultrasonic units. The programming is performed by entering the dimensions in the software with the device connected using the supplied USB. If readings appear off, the settings in the software should be checked and adjusted.

Date published: 2022-09-19