Resistance Temperature Devices (RTDs) are widely used in industrial and commercial applications due to their accuracy and stability. However, RTD wire configuration can significantly impact measurement precision. Selecting the right configuration ensures optimal performance, minimizes errors, and enhances system reliability.

Understanding RTD Wire Configurations

RTDs are typically manufactured in three different wiring configurations: 2-wire, 3-wire, and 4-wire. Each configuration is designed to compensate for lead wire resistance to varying degrees, impacting measurement accuracy. The 2-wire setup is the simplest but most susceptible to errors from lead resistance, making it suitable for shorter wire runs or applications where high precision is not critical. The 3-wire configuration offers better compensation and is commonly used in industrial settings where moderate accuracy is required. The 4-wire configuration provides the highest level of accuracy by fully eliminating lead wire resistance effects, making it ideal for laboratory and high-precision applications.

2-Wire RTDs: Simple but Limited

A 2-wire RTD is the most basic configuration, consisting of a sensing element with a single lead wire connected to each end. This setup makes it the simplest and most cost-effective RTD configuration available. However, because the lead wire resistance is included in the total resistance measurement, it can introduce significant errors, particularly in applications with long cable runs.

-

Configuration: A single lead wire connects to each end of the RTD element.

✔ Pros: High accuracy and reliability

✖ Cons: Requires stopping flow for installation or removal

Best For: Short-distance applications where high precision is not critical, such as basic temperature monitoring.

3-Wire RTDs: The Industrial Standard

A 3-wire RTD is the most commonly used configuration in industrial applications. It features two wires connected to one side of the RTD element and a single wire on the other. This design helps compensate for lead wire resistance by assuming that both lead wires have the same resistance. While this assumption generally holds true in controlled environments, minor inaccuracies may still arise if wire lengths or resistances are unequal.

-

Configuration: Two wires on one side of the RTD element and one wire on the other.

✔ Pros: Cost-effective and easy to install

✖ Cons: Lead wire resistance is included in the measurement – leading to potential inaccuracies, particularly with longer cable runs.

Best For: Short-distance applications where high precision is not critical, such as basic temperature monitoring.

4-Wire RTDs: Maximum Precision

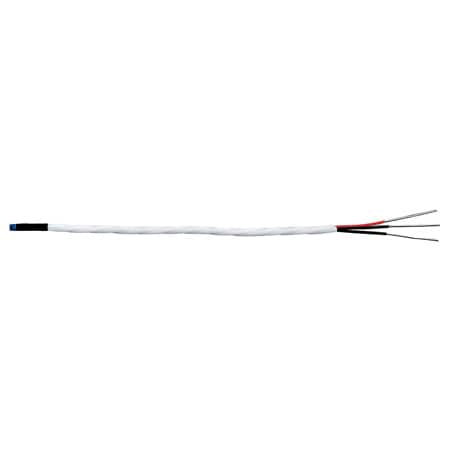

A 4-wire RTD is the most accurate configuration, designed to completely eliminate the effects of lead wire resistance. It utilizes two wires on each end of the RTD element, allowing precise resistance measurement by using a separate pair of wires for excitation and measurement. This configuration is commonly used in laboratory and high-precision industrial applications where measurement errors must be minimized.

-

Configuration: Two wires on each end of the RTD element, allowing the instrument to completely eliminate lead wire resistance from the measurement.

✔ Pros: Provides the highest accuracy by completely compensating for lead wire resistance.

✖ Cons: More complex wiring and higher cost.

Best For: High-precision applications – such as laboratory research, calibration systems, and critical industrial processes.

Choosing the Right RTD Configuration

Selecting the appropriate RTD configuration depends on the application’s accuracy requirements, wiring complexity, and budget. A 2-wire RTD may be sufficient for shorter runs or less critical measurements, while a 3-wire setup balances accuracy and cost for many industrial applications. For the highest precision, a 4-wire RTD is preferred, though it requires more complex wiring and higher installation costs.

Environmental factors such as electrical noise and temperature fluctuations should also be considered, as they can influence measurement accuracy and may necessitate a more robust configuration. Additionally, the type of instrumentation used to process the RTD signal plays a role in determining the most suitable wiring setup, as some systems are designed to work optimally with a specific configuration. Proper installation and maintenance further ensure long-term reliability, preventing errors caused by degraded connections or improper wiring practices.

Discover DwyerOmega's Comprehensive Selection of Temperature Measurement Devices Here!