Welcome to our new website, found an issue or bug? Please report it here

SA1-RTD-Series

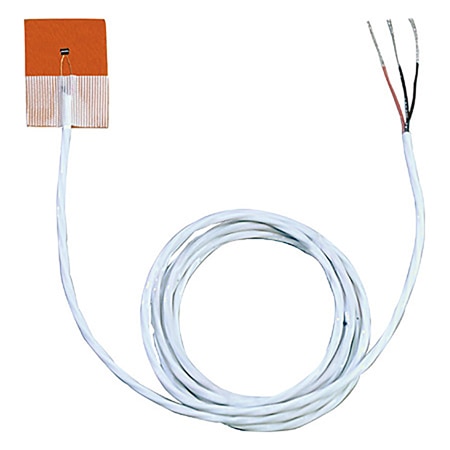

Self-Adhesive Polyimide Fast Response RTD Surface Sensors, Class A Accuracy

Models In Stock

- 100 Ω DIN Class A (± 0.06 Ω or ± 0.15°C at 0°C) Accuracy Standard

- Easy-Installation Silicone-Based, Self-Adhesive Backing Rated to 260°C (500°F)

- Back Can be Reapplied

- Temperature Range -73C to 260°C Continuous, 290°C (554°F) Short Term Operation When Installed with OMEGABOND Air Set Cements

SA1-RTD-Series

From

$

112.91

Models In Stock

Can't find the right model?

Use our custom configurator to fine tune your product

Product Overview

- Accuracy Class A

- Accuracy Note 100 Ω DIN Class A (± 0.06 Ω or ± 0.15°C at 0°C) Accuracy Standard

- Cable Material Nickel, Copper

- Insulation PFA

- Mounting Class DIN Platinum

- Nominal Resistance 100 Ω

- Process Temperature, Max 260 °C

- Process Temperature, Min -73 °C

- Response Time In Water Immersion : <0.9 sec ; On a Hot Plate: <2 sec

- Self Heating Effect 0.40 °C / mW

- Stability <0.2 °C

- Stability Note Stability: Less than 0.2°C drift/year

- Temperature Coefficient 0.00385 Ω/Ω/°C

- Temperature Coefficient Note α = 0.00385 Ω/Ω/°C

- Temperature Sensor Type RTD

- Wire Gauge 26 AWG

The SA1-RTD surface-mount RTD temperature sensor mounts on flat or curved surfaces and provides Class A accuracy for critical temperature monitoring applications. Based on a 2 x 2 x 0.8 mm thin-film platinum RTD and supplied with bare 3-wire leads as a standard configuration (connector optional), itcan be customized for use in a wide variety of applications. The sensor can be easily applied with its selfadhesive

backing, or positioned permanently with OMEGABOND™ cements.

Use the SA1-RTD to monitor chip, heat sink, and environmental temperatures in electronic devices; check piping or ducting temperatures;monitor motor and transformer core heat; test insulation capabilities; and check other applications in which surface and/or gradient temperatures need to be monitored or controlled.

PDFs & Manuals

Accessories

SA1-RTD Surface-Mount RTD Temperature sensor | Quick Shipment

$191.36

0 In Stock

Show Ratings & Reviews

Rated 5 out of

5

by

SolarCowboy from

BOM sensor

I ordered temperature sensors to monitor solar panels temperature to analyze performance

Date published: 2016-10-23

Rated 4 out of

5

by

Peter R from

Works great

Does exactly what it says it does. Installed easily with epoxy from omega. Plenty accurate for our purposes. Cost effective

Date published: 2017-02-28

Rated 5 out of

5

by

2NinerRomeo from

These things work great

They shipped fast, and appear to have great accuracy and low noise,

Would buy again.

Date published: 2024-12-10

Rated 5 out of

5

by

Zallcom from

Perfect service five stars

It was perfect, i enjoyed working with you . I will shop again next time

Date published: 2024-05-26

Rated 5 out of

5

by

Yavne G CTM Magnetics from

Great Purchase

good quality product.

customer service is always there to help

Date published: 2024-02-15

Rated 5 out of

5

by

Zac1 from

RTD Sensor

RTD's worked as we expected and were easy to order.

Date published: 2023-10-16

Rated 5 out of

5

by

Anonymous from

Good customer service and quality product.

Worked as expected, purchase was easy and customer service rep was very helpful and answered all my questions before order.

Date published: 2023-07-18

Rated 5 out of

5

by

PPro Engineering from

Communication

There were some issues with raw materials and was never communicated. I had to expedite the order to find out that the order has been delayed. However, Omega was very helpful to escalate the issue and sort out the raw material issue in good time.

Date published: 2023-05-26

I'm interested in purchasing one of these, but I can't find information regarding acceptable current bounds; can you give me an estimate on minimum required current to operate this sensor, and maximum not to toast it?

Hi EAML,

Normal excitation current is 1mA or less. Minimum current level is determined by the instrument being used.

Higher levels will cause readings to be affected by self heating errors. We do not have established current level which can cause burnout.

Best regards

OMEGA

Date published: 2020-06-09

It says, 'back can be reapplied' in the product description. Is there back adhesive material that can be used for this RTD?

The SA1-RTD if carefully removed can be reattached but each time will lose some of its adherent properties. Sometimes when it no longer sticks a piece of Kapton tape can be laid over the top to hold it in place,

Date published: 2020-04-15

Hi, could you please send me or link here a "Resistance vs Temperature table" for the SA1-RTD (3 wires)? Regards.

Thank you for your inquiry Sborzy. Please review the following link for the table: https://assets.omega.com/tech-ref-legacy-pdfs/z252-254.pdf

Date published: 2022-08-25

What is the best method to cut the PFA wire covering to get access to more of the leads?

Omega sells the TW-6 which is designed to remove the outer insulation of wires with ease. You can enter TW-6 in the search box on Omega's web page for further details.

Date published: 2020-05-11

In the spec sheet, there are tolerances listed for down to -200°C. My application requires use down to -100°C; is -73°C the cutoff for optimal precision, or does the sensor stop working below this minimum temperature rating?

These RTD probes will work down to -100C and lower but the adhesive is not effective below-73C so the should be mechanically secured.

Date published: 2024-02-23

What is the recommended method of calibrating these sensors?

Thank for your inquiry. Surface Wire Sensor when calibrated, is done before the adhesive pad is attached. Not after. We recommend purchase calibrated sensors from OMEGA.

Date published: 2023-07-26

How to calculate temperature error for adhesive film between RTD and surface? How much error should I expect from the adhesive if my surface temperature is 100C and air temperature is 25C?

Hi TEBrian,

Thank you for the inquiry. Please forward this question to TEMP@OMEGA.COM.

Best regards,

OMEGA

Date published: 2023-08-02

The data sheet mentions installation using Omegabond thermal epoxy. What is the correct/recommended process for epoxy install? Does the polyimide tape get completely removed, and then epoxy the RTD on? Seems like tape on epoxy would not create a good bond

Thank you for your inquiry RPeebs. You will need to use thermal conductive epoxy that way you don't block the heat from coming into contact with the probe. The pad should not affect the temperature measurement if you decide to use epoxy in conjunction with the adhesive pad.

Date published: 2022-08-25