1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

PX600

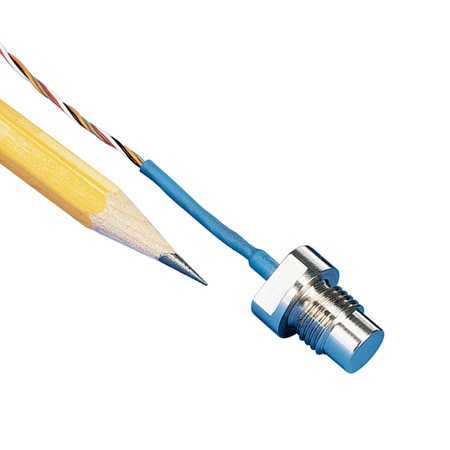

Subminiature, Flush Diaphragm Pressure Transducers

Models In Stock

- All Stainless Steel Diaphragm and Threaded Side Wall Construction

- Rugged Stainless Steel Case Protects Components in Industrial Environments

- Uses a Standard 5 Vdc Regulated Power Supply for Maximum Versatility

- Custom Subminiature Design Techniques Provide Small Size and Preserves Accuracy

PX600

From

$

829.17

Models In Stock

Product Overview

- Accuracy ± 1 %

- Accuracy Class > 0.25%

- Accuracy Detail ± 1% FS (linearity and hysteresis combined)

- Additional Features 1 None

- Burst Pressure Note 400% range

- Compensated Temperature, Max 71 °C

- Compensated Temperature, Min 16 °C

- Electrical Output 2 mV/V

- Enclosure Material 17-4 PH Stainless Steel

- Input Resistance 350 Ω

- Insulation Resistance 5 MΩ @ 75 Vdc

- Materials, Wetted FKM

- Operating Temperature, Max 121 °C

- Operating Temperature, Min -54 °C

- Output Resistance 350 Ω

- Repeatability Error ± 0.1% FS

- Sensitivity 2 mV/V nominal

- Sensitivity Effect ± 0.036% reading/°C

- Supply Power Note 5 Vdc @15 mA

- Supply Voltage 5 Vdc

- Weight 14 g

- Zero/Balance Error ± 3% FS

SPECIFICATIONS

Excitation: 5 Vdc @15 mA

Output: 10 mV typical @ 5 Vdc

Sensitivity: 2 mV/V

Nominal Input Impedance: 360 Ohms min

Output Resistance: 350 Ohms min Insulation

Resistance: 5 MOhms @ 75 Vdc

Accuracy: ± 1% FS( Linearity and Hysteresis combined)

Repeatability: ± 0.1% FS

Zero Balance: ± 3% FS

Operable Temperature Range: -65 to 250°F (-54 to 121°C)

Compensated Temperature Range: 60 to 160°F (16 to 71°C)

Thermal Zero Effect: less than ± 0.01% full scale/°F

Thermal Sensitivity Effect: ± 0.02% Reading/ °F

Proof Pressure:150% Range

Burst Pressure: 400% Range

Body and Diaphragm Material: 17-4 PH Stainless Steel

O-Ring: 2-011 Polyvinyl: 2-011-P $15/10 pack

FKM: 2-011-V $10/10 pack

Electrical Connection: 4 Cond Cable

Weight: 0.5 oz (14 g)

Compatible meters: DP41-S**, DP25-S**

Excitation: 5 Vdc @15 mA

Output: 10 mV typical @ 5 Vdc

Sensitivity: 2 mV/V

Nominal Input Impedance: 360 Ohms min

Output Resistance: 350 Ohms min Insulation

Resistance: 5 MOhms @ 75 Vdc

Accuracy: ± 1% FS( Linearity and Hysteresis combined)

Repeatability: ± 0.1% FS

Zero Balance: ± 3% FS

Operable Temperature Range: -65 to 250°F (-54 to 121°C)

Compensated Temperature Range: 60 to 160°F (16 to 71°C)

Thermal Zero Effect: less than ± 0.01% full scale/°F

Thermal Sensitivity Effect: ± 0.02% Reading/ °F

Proof Pressure:150% Range

Burst Pressure: 400% Range

Body and Diaphragm Material: 17-4 PH Stainless Steel

O-Ring: 2-011 Polyvinyl: 2-011-P $15/10 pack

FKM: 2-011-V $10/10 pack

Electrical Connection: 4 Cond Cable

Weight: 0.5 oz (14 g)

Compatible meters: DP41-S**, DP25-S**

PDFs & Manuals

Show Ratings & Reviews

Hi, Can the PX600-10KGV be ordered with TWISTED TEFLON wires (or is it already the case in this product), also do you offer the same transducer with 15000 psi range ? Thanks Omar

Thank you for contacting Omega. The PX600 series transducers come standard with a Teflon insulated lead wire. Sorry but the highest range available is the 0 to 10,000 psi range.

Date published: 2019-10-01

What is the safe overload of this transducer? (Specifically the 5K and 10K variants) Is there a possibility to adapt this thread to SAE-2 (5/16-24 per J1926-2) with a custom thread adapter or would that blow out at high pressures near FS?

Maximum safe overpressure (proof pressure) is 150% of the sensors rated pressure range. A 5/16-24 thread has a max pressure of 6000 PSI so it would work for the 10,000 PSI range unit

Date published: 2023-03-11

What is the response time of these sensors? I would like to use these to characterize a gear pump and need to be able to capture pressure pulses over 400 Hz.

Thank you for your inquiry

While this sensor has not been specifically tested for response time, typical for strain gage pressure sensors is a response time of 1kHz.

Hope this helps.

Date published: 2020-09-23

Does these contain silicon oil in the sensing element?

The PX600 Series pressure transducers do not contain any type of oil fill.

Date published: 2024-03-23

When threading the PX-600 into the housing, we noticed an increase on the pressure when the torque increase. Is this behavior considered normal? if so, could you provide the recommended torque setting for the installation?

It is normal to see an increase in the output signal tightening the sensor during installation. Design engineering suggests a torque value of 260 in-lbs. You would then correct for the reading offset at zero pressure in the scaling of your readout device.

Date published: 2023-09-11

Do you have mounting dimensions details for 3/8-24 UNF threads? there is no information in the drawing about mounting the sensor. Thank you

Yes. There is a dimensional drawing for the mating port for the PX600. Please contact a technical representative at pressure@omega.com to acquire the drawing

Date published: 2020-08-08

What does the small "balance" circuit board do that you find in the wiring of the sensor do? Is this board the same for all sensors of this type, or is the board specific to each sensor?

The external balance board is for designed to correct for any zero offset you have in the internal strain gage bridge internal to the sensor. It's external due to the very small size to the body of sensor. Each balance board is trimmed specifically to the sensor. They are not interchangeable.

Date published: 2022-11-18