1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

LC103B

High Accuracy, Stainless Steel, S-Beam Load Cells

Models In Stock

- Available in capacities from 25 to 20,000 lbs and 25 to 10,000 kg

- Stainless steel, sealed by adhesive inside, oil-proof, waterproof and anti-corrosion, suitable for all kinds of environments.

- S beam design, tension and/or compression loading possible, easy installation, suitable for crane scale, mechanical conversion scale, hopper scale and other electronic weighing devices.

- Provided with a certificate of conformance and full-scale calibration.

LC103B

From

C$

275.00

Models In Stock

Product Overview

- 5-Point Calibration 0%, 100%

- Accuracy Class C3

- Calibration Option 2 POINT NIST

- Dead load 0% FS

- Enclosure Ratings IP67

- Force Type Compression, Tension

- Full Scale Deflection 0.0317 in

- Hysteresis ± 0.035%

- Input Resistance 430 ± 50 Ω

- Insulation Resistance ≥ 5000 MΩ

- Linearity ± 0.035%

- Load Cell Type S-beam

- Materials Stainless Steel

- Number of Load Cell Intervals (nLC) 3000

- Operating Temperature, Max 65 °C

- Operating Temperature, Min -35 °C

- Output Resistance 351 ± 2 Ω

- Overload, Max 300% FS

- Process Temperature, Max 40 °C

- Process Temperature, Min -10 °C

- Ratio of Minimum LC Verification Interval (Y = Emax/vmin) 10000

- Repeatability ± 0.035%

- Safe Overload 150% FS

- Storage Temperature, Max 70 °C

- Storage Temperature, Min -40 °C

- Supply Power Note 5 to 12 Vdc, 18 Vdc max

- Supply Voltage 5 to 12 Vdc

- Zero/Balance Error ± 1%

Omega's new LC103B S-Beam load cells are compact and provide superior performance for tension or compression loading. This design provides excellent linearity and temperature performance, meeting OIML R60 C3 accuracy class for legal metrology applications.

Rugged stainless steel construction and precision sealing provide anti-corrosion and IP67 ingress protection suitable for all kinds of environments.

S-Type load cells that receive tension or compression forces. Applications include tank weighing, hoppers, suspended loads and truck scales. S-Type load cells provide superior performance in a compact, versatile package.

Specifications:

Hysteresis: +/-0.035%

Linearity: +/-0.035%

Repeatability: +/-0.035%

Accuracy (>25lb): class C3

Approvals(>25lb): OIML R60

Output sensitivity (mV/V): 3.0± 0.008 (≠¤25lb 2.0± 0.006)

Maximum number of load cell intervals (nLC): 3000

Ratio of minimum LC verification interval (Y=Emax/vmin): 10000

Combined error (%FS): ± 0.020

Minimum dead load: 0

Safe overload (%FS): 150%

Ultimate overload (%FS): 300%

Zero balance (%FS): ± 1.0%

Excitation, recommended voltage (V): 5 to 12(DC)

Excitation maximum (V): 18(DC)

Input resistance (Ω): 430 ± 50

Output resistance (Ω): 351 ± 2

Insulation resistance (MΩ): ≠¥ 5000 (50VDC)

Compensated temperature (°C): -10 to 40

Operating temperature (°C): -35 to 65

Storage temperature (°C): -40 to 70

Element material: Stainless steel

Ingress protection (according to EN 60529): IP67

Recommended torque on fixation (Thread:lbf.ft):1/4"UNF:18 1/2"UNF:55 3/4"UNF:330 1"UNF:550 1 1/8"UNF:1070

Recommended torque on fixation (Thread:Nm):M8:25 M12:75 M20:450 M24:750 M30:1450

Nominal full scale deflection range: 0.1935---0.8065(mm)

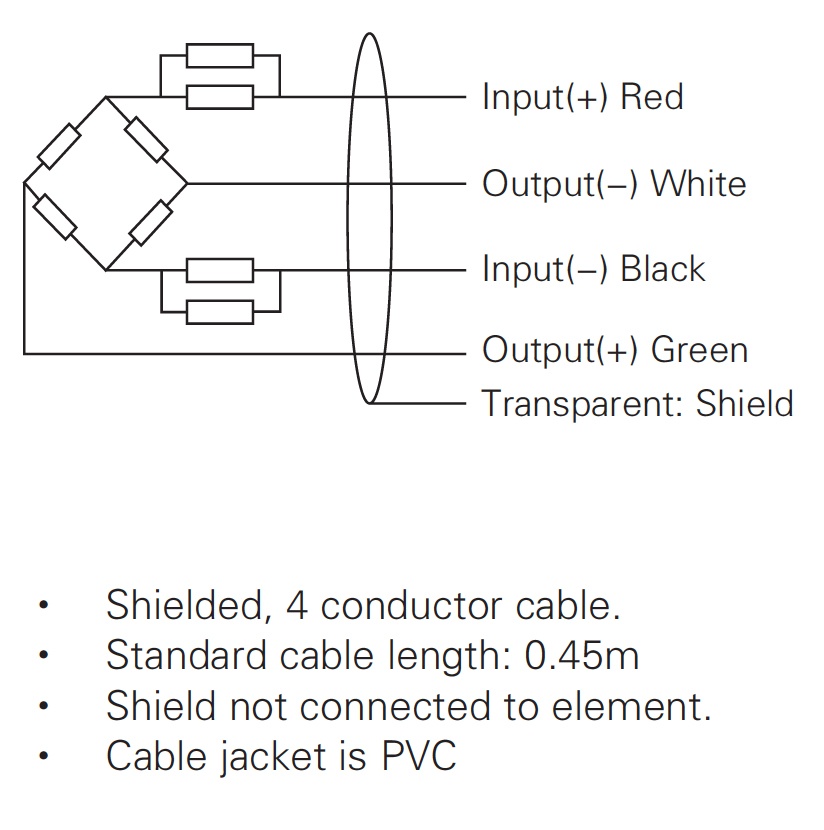

Wiring

Shielded, 4 conductor cable

Cable diameter: à˜5mm

Standard cable length: 6m

Shield not connected to element

Rugged stainless steel construction and precision sealing provide anti-corrosion and IP67 ingress protection suitable for all kinds of environments.

S-Type load cells that receive tension or compression forces. Applications include tank weighing, hoppers, suspended loads and truck scales. S-Type load cells provide superior performance in a compact, versatile package.

Specifications:

Hysteresis: +/-0.035%

Linearity: +/-0.035%

Repeatability: +/-0.035%

Accuracy (>25lb): class C3

Approvals(>25lb): OIML R60

Output sensitivity (mV/V): 3.0± 0.008 (≠¤25lb 2.0± 0.006)

Maximum number of load cell intervals (nLC): 3000

Ratio of minimum LC verification interval (Y=Emax/vmin): 10000

Combined error (%FS): ± 0.020

Minimum dead load: 0

Safe overload (%FS): 150%

Ultimate overload (%FS): 300%

Zero balance (%FS): ± 1.0%

Excitation, recommended voltage (V): 5 to 12(DC)

Excitation maximum (V): 18(DC)

Input resistance (Ω): 430 ± 50

Output resistance (Ω): 351 ± 2

Insulation resistance (MΩ): ≠¥ 5000 (50VDC)

Compensated temperature (°C): -10 to 40

Operating temperature (°C): -35 to 65

Storage temperature (°C): -40 to 70

Element material: Stainless steel

Ingress protection (according to EN 60529): IP67

Recommended torque on fixation (Thread:lbf.ft):1/4"UNF:18 1/2"UNF:55 3/4"UNF:330 1"UNF:550 1 1/8"UNF:1070

Recommended torque on fixation (Thread:Nm):M8:25 M12:75 M20:450 M24:750 M30:1450

Nominal full scale deflection range: 0.1935---0.8065(mm)

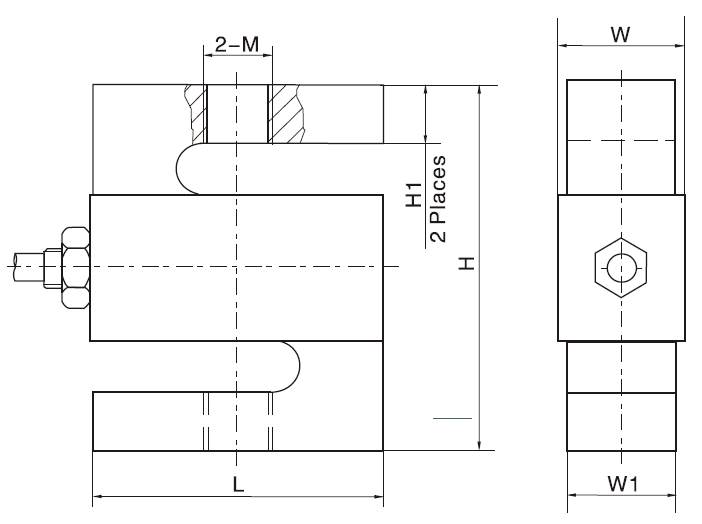

| Capacity | L mm(in) | H mm(in) | H1 mm(in) | W1 mm(in) | W mm(in) | M(thread) |

|---|---|---|---|---|---|---|

| 25 to 300 lbf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.4) | 11.96 (0.5) | 15.06 (0.6) | 1/4-28UNF |

| 500 to 1500 lbf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.4) | 18.03 (0.7) | 21.4 (0.8) | 1/2-20UNF |

| 2000 to 2500 lbf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.4) | 24.38 (1.0) | 27.76 (1.1) | 1/2-20UNF |

| 3,000 lbf | 76.2 (3.0) | 99.06 (3.9) | 13.97 (0.55) | 24.38 (0.96) | 27.76 (1.09) | 1/2-20UNF |

| 5000 lbf | 76.2 (3.0) | 99.06 (3.9) | 13.97 (0.6) | 24.38 (1.0) | 27.76 (1.1) | 3/4-16UNF |

| 10,000 lbf | 74.68 (2.9) | 99.06 (3.9) | 15.75 (0.6) | 30.74 (1.2) | 34.12 (1.3) | 3/4-16UNF |

| 20,000 lbf | 112.8 (4.4) | 177.8 (7.0) | 39.9 (1.6) | 42.93 (1.7) | 46.31 (1.8) | 1 1/4-12UNF |

| METRIC | ||||||

| 25kg | 76.2 (3.0) | 50.8 (2.0) | 12.7 (0.5) | 16.1 (0.63) | 15.7 (0.62) | M8 |

| 50 kgf to 100 kgf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.35) | 11.68 (0.46) | 15.06 (0.59) | M8 |

| 250 kgf to 500 kgf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.35) | 18.03 (0.71) | 21.4 (0.84) | M12 |

| 1,000 kgf | 50.8 (2.0) | 60.96 (2.4) | 8.89 (0.35) | 24.38 (0.96) | 27.76 (1.09) | M12 |

| 2,500 kgf | 76.2 (3.0) | 99.06 (3.9) | 13.97 (0.55) | 24.38 (0.96) | 27.76 (1.09) | M20 x 1.5 |

| 5,000 kgf | 74.68 (2.94) | 99.06 (3.9) | 18.37 (0.72) 15.75 (0.62) | 30.74 (1.21) | 34.12 (1.34) | M20 x 1.5 |

| 7,500 kgf | 87.38 (3.44) | 139.7 (5.5) | 27.5 (1.08) | 37.08 (1.46) | 40.46 (1.59) | M24 x 2 |

| 10,000 kgf | 112.78 (4.44) | 177.8 (7.0) | 39.9 (1.57) | 42.93 (1.69) | 46.31 (1.82) | M30 x 2 |

Shielded, 4 conductor cable

Cable diameter: à˜5mm

Standard cable length: 6m

Shield not connected to element

PDFs & Manuals

Show Ratings & Reviews

Rated 1 out of

5

by

macusson from

Incorrect Part & Extra Costs Due to Website Error

Issue with Order: We experienced a significant issue with our order due to an error in the website's part identification system. This error led to the receipt of an incorrect part, which was not only inconvenient but also added unnecessary costs to our project.

Cost Impact: The mistake resulted in an additional expense of $300 over our original budget. This overcharge was a direct consequence of the website error, placing an unforeseen financial burden on our project.

Incorrect Part Received: Instead of the PigTail part we initially ordered, we received a connector. This mix-up was further complicated when the representative provided us with the wrong part number during our attempt to resolve the issue.

Overall Experience: The combination of the website's identification error, the additional costs, and the receipt of the wrong part has been highly disappointing. It has caused delays and financial strain on our project, which could have been avoided with a more accurate and reliable ordering system.

Recommendation for Improvement: We urge the supplier to review and improve their website's part identification process to prevent such errors in the future. Clearer communication and more accurate assistance from customer service representatives would also be beneficial.

Date published: 2023-12-08

Rated 5 out of

5

by

Stretch from

Easy Installation

M8 mounting screws for easy installation and 3 m cable for direct wiring to signal conditioner

Date published: 2020-12-21

Rated 5 out of

5

by

omega load cells from

Great Load cells

Very accurate heavy duty load cells and easy to install.

Date published: 2025-02-08

Rated 3 out of

5

by

Apex from

Plant manager

Called for sport never heard back. From their support department

Date published: 2024-06-23

Rated 5 out of

5

by

Progressive Electric from

LC103B-250lb load cell

Great load cell for the cost of the item. We used LC101-250 before, but the new model is great.

Date published: 2023-11-06

Rated 5 out of

5

by

Chris M from

Load cell application - high power rockets

We have used these for years in harsh conditions (desert environment) and they always perform flawlessly.

Date published: 2023-04-15

Rated 5 out of

5

by

Product Engineer Maradyne from

Dyno Load Cell for use in Product development

Quick service, prompt delivery, excellent packaging, courteous personnel

Date published: 2023-03-20

Rated 5 out of

5

by

Justin Nichols from

Solid Product

Couldnt have asked for a better product very solid and realiable.

Date published: 2023-02-09

How can I get the datasheet for the load cell? The datasheet provided in the link brings me to a datasheet for cable assemblies and twist connectors instead of the load cell.

There is currently no datasheet available for the LC103B Series load cells. If you scroll down to the bottom of the LC103B product page on our website you will find complete specifications, wiring and dimensions.

Date published: 2025-04-04

Hi, Dose this load cell have CSA, cUL, or any other regulatory approval.

Maik, thank you for contacting Omega Engineering. At this time we do not unfortunately have any of the above approvals.

Date published: 2021-08-18

Is this load cell compatible with a National Instruments chassis? Does this load cell require a special DAC?

This load has an internal 3mV/V sensitivity full strain gage bridge. NI offers input boards designed to take this type of input. We do not know the exact model number of this input board so you have to check with NI directly

Date published: 2021-12-28

Are the threads on the LC103B-100 Load Cell right handed threads on both sides of the load cell? I just want to make sure it isn't like a turn buckle where there is a left handed thread on one side and a right handed thread on the other side.

Thank you for your question, these are right-handed threads.

Date published: 2020-12-06

Do you have the datasheet?

Thank you for your inquire

The data sheets are now being added below the order page.

Date published: 2024-07-24

What is the threadcount and diameter requirement for the heim joints?

Shane, the internal thread on the LC103B-100 model will be 1/4-28UNF. Thank you.

Date published: 2019-11-23

Were can I find the datasheet/pin-out/color coding etc?

LC113B models < 300 lbs uses 4-pin connector, and LC113B models > 300 lbs use 6 pin connector.

Pin out will be:

4 pin : A = + Out B = - Out C = -Input D = +Input

6 pin : A = + Out B = - Out C = -Input D = +Input E and F = NO CONTACT

One of our Application engineers has reached out to you regarding this case, in case you need more assistance feel free to reach us at 1800 622 2378

Date published: 2024-04-05

The LC101 page says that series is being replaced by the new and improved LC103B series. What is improved? LC103B appears to have greater error (linearity, hysteresis, repeatability) but is bi-directional for less than half the cost. Is that it?

You are correct. Combined accuracy calculation for LC103B does work out to 0.060% opposed to 0.037% of the LC101. We should consider calling this load cell a more economical replacement of LC101 rather than an improved version.

Date published: 2022-08-02