KFH-Linear

Pre-Wired Strain Gauges for Easy Installation

Models In Stock

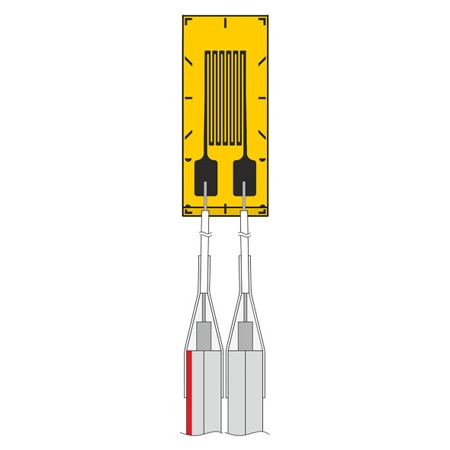

- Pre-Wired Gages Make Installations Easy!

- No Soldering at the Measuring Point

- Sold in Packs of Ten

- Each Gage has 50 mm of PTFE Cable before Transitioning to AWG 28 Leads to Prevent Leads from Adhering During Installation

KFH-Linear

From

C$

153.55

Models In Stock

Product Overview

- Adhesive SG496, SG401, TT300

- Carrier Thickness 45 μm

- Elongation 20000 µm/m to 25000 µm/m

- Gauge Factor 2

- Gauge Factor Tolerance ± 1 %

- Grid Length Range 3 mm

- Grid Style Linear

- Grid Thickness 5 μm

- Material Construction Option Steel

- Materials Constantan, Polyimide

- Mechanical Life >10^7 cycles

- Mechanical Life Note >1 x 107 cycles at zero point variation ≤ 300 µm/m, 5 x 106 cycles at zero point variation ≤ 30 µm/m

- Operating Temperature, Max 155 °C

- Operating Temperature, Min -10 °C

- Pack Size 10

- Sensitivity ±0.2%

- Temperature Compensation 10.8 x 10-6

- Tolerance ±1%

Linear pattern precision pre wired gages with minature and medium length grids are for general purpose and stress analysis applications. Available with either two 1-meter leads or three 3-meter leads and 120 Ω or 350 Ω resistance. All models are compensated for steel.

Specifications See Spec Sheet for full specifications

Strain Gage Construction Foil strain gage with embedded measuring grid

Measuring Grid

Material Constantan

Thickness µm (microinch) 3.8 or 5 (150 or 197), depending upon strain gage type

Carrier Material Polyimide

Thickness µm (microinch) 45 ± 10 (1.772 ± 394)

Connections PTFE wire, Ø - 0.051 mm², approximately 50 mm long, connected to AWG 28 ribbon cables (PVC insulated) through solder sleeves in 2- or 3-wire configurations

Nominal Resistance Ω 120 or 350 depending upon gage

Resistance Tolerance % ±0.35, with 0.6 mm and 1.5 mm grid length % ±1

Gage Factor approximately 2 (stated on package)

Gage Factor Tolerance % ±1, with 0.6 mm and 1.5 mm grid length % ±1.5, temperature coefficient of gage factor 1/K [1/°F] (115 ± 10) x 10-6 [(64 ± 5.5) x 10-6, nominal value of gage factor temperature coefficient Specified on each package

Applicable Bonding Materials

Cold Cure Adhesives SG496, SG401

Heat Cure Adhesives TT300

Specifications See Spec Sheet for full specifications

Strain Gage Construction Foil strain gage with embedded measuring grid

Measuring Grid

Material Constantan

Thickness µm (microinch) 3.8 or 5 (150 or 197), depending upon strain gage type

Carrier Material Polyimide

Thickness µm (microinch) 45 ± 10 (1.772 ± 394)

Connections PTFE wire, Ø - 0.051 mm², approximately 50 mm long, connected to AWG 28 ribbon cables (PVC insulated) through solder sleeves in 2- or 3-wire configurations

Nominal Resistance Ω 120 or 350 depending upon gage

Resistance Tolerance % ±0.35, with 0.6 mm and 1.5 mm grid length % ±1

Gage Factor approximately 2 (stated on package)

Gage Factor Tolerance % ±1, with 0.6 mm and 1.5 mm grid length % ±1.5, temperature coefficient of gage factor 1/K [1/°F] (115 ± 10) x 10-6 [(64 ± 5.5) x 10-6, nominal value of gage factor temperature coefficient Specified on each package

Applicable Bonding Materials

Cold Cure Adhesives SG496, SG401

Heat Cure Adhesives TT300

PDFs & Manuals

Show Ratings & Reviews

Rated 5 out of

5

by

MSilva from

Great performance

Precise. We will keep using this sensor from Omega.

Date published: 2017-08-09

Rated 3 out of

5

by

smlt from

I only buy these when I run out of others.

These gages work fine once I get them installed. But the heavy wire splices near the gage complicates installation. The hook up end is just a tiny bit of bare wire - my preferred brand always makes long tinned ends which can be put directly around a screw terminal.

Date published: 2016-06-13

Rated 5 out of

5

by

Anonymous from

PRE-WIRED STRAIN GagesS

When it comes to measuring strain in various applications, the convenience and accuracy of the equipment you use can make a significant difference. In this review, we will be discussing the merits of Pre-Wired Strain Gauges, a tool that has increasingly gained popularity in the world of engineering and materials testing.

Date published: 2023-10-23

Rated 5 out of

5

by

Tom H from

Easy

Prewired saves me the effort of soldering. I have applied these to over 20 prototype devices that require force feedback. They have functioned reliably for "long" periods of time (2 years and counting) I apply them to Aluminum plates with Loctite 401.

Date published: 2022-10-21

If strain is dimensionless why the maximum strain is given in micrometer?

Hi.

I know strain is dimensionless but, on this website on the description of these strain gauges says maximum strain 50 000 micrometers. My question is why this strain gauges are being rating in micrometers.

Date published: 2024-08-21

How do I wire this strain gauge to Bridge data logger OM-CP-Bridge101A? Which ports on the green connector? How do I monitor 2 strain gauges on this bridge?

Thank you for your inquiry. Either single strain gage or full bridge is supported. Please email our Data Acquisition Group at das@omega.com for complete wiring details.

Date published: 2023-02-06

Whats the difference between the 2-wire and 3-wire configuration? What signal does each wire carry?

Hi, typically 3-wire strain gauges are used for lead wire temperature compensation. If the strain gauge is a 2-wire system, strain output from the bridge is affected by the temperature effect of the lead wire. To avoid such adverse effect, the 3-wire system is adopted. If 3 lead wires are connected to a strain gage, a half lead wire resistance is applied to the adjacent side of a bridge to compensate for the temperature effect of lead wires in bridge output. The temperature effect of the lead wires connected to a measuring instrument outside of the bridge is ignored because the input impedance of the measuring instrument is high. Our Tech Support engineer has also emailed you images to help answer your question. Email us back anytime if you need any further assistance. Thanks

Date published: 2020-09-08

Does each linear pre-wired strain gauge contain a full Wheatstone bridge or would I have to purchase 4 to create one myself?

The KFH is a linear, single grid strain gauge. It is not a full Wheatstone bridge. Our Tech Support has emailed you a diagram of what complete Wheatstone bridge likes. Please contact our Tech Support if you have any further questions. Thank you.

Date published: 2020-02-18

Is this priced per pack of 10?

Thanks for your question. Yes, these are priced per pack of ten.

Date published: 2019-04-22

Can these gauges be reused after being removed from a specimen?

Thank you for your question?

Most strain gauges will not work once they have been removed from a glued surface.

However you can try and have had some customers succeed in doing it onetime.

Date published: 2019-06-25

The price listed is for a 10 pack (Qty. 10) pre-wired strain gauges, correct?

Hello, you are correct, the KFH series is sold as a pack of 10

Date published: 2024-05-02

How to connect wires of this SG to a 3-wire input system with EXC, AI, and RC inputs, such as NI-9236?

Tackoo, thank you for contacting Omega Engineering. Please see page 10 of the NI9236 Manual, the 2 lead wires from the strain gauge will connect to EXC and RC, then you will have to add an external jumper across AI and RC. It might be better to contact NI if you have more wiring questions.

Date published: 2020-09-09