1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

PX3005K

Sanitary, Rangeable, Pressure Transmitters with Display

Models In Stock

- Pressure Transducer for Sanitary or CIP (Clean-in-Place) Applications

- Meets 3-A sanitary standards for food, beverage, dairy, and pharmaceutical applications

- IP67 316 SS enclosure protects against harsh environments

- 5 digit display for easy monitoring

PX3005K

From

C$

1 583.37

Models In Stock

Product Overview

- Accuracy ± 0.2 %

- Accuracy Class 0.1% to 0.25%

- Accuracy Detail ± 0.2TD% SPAN

- Electrical Connection M12 4 pin Male

- Electrical Output 4 to 20 mA

- Electrical Output Note 4 to 20 mA Two wire

- Operating Temperature, Max 70 °C

- Operating Temperature, Min -20 °C

- Output Signal Current

- Pressure Type Compound Gauge

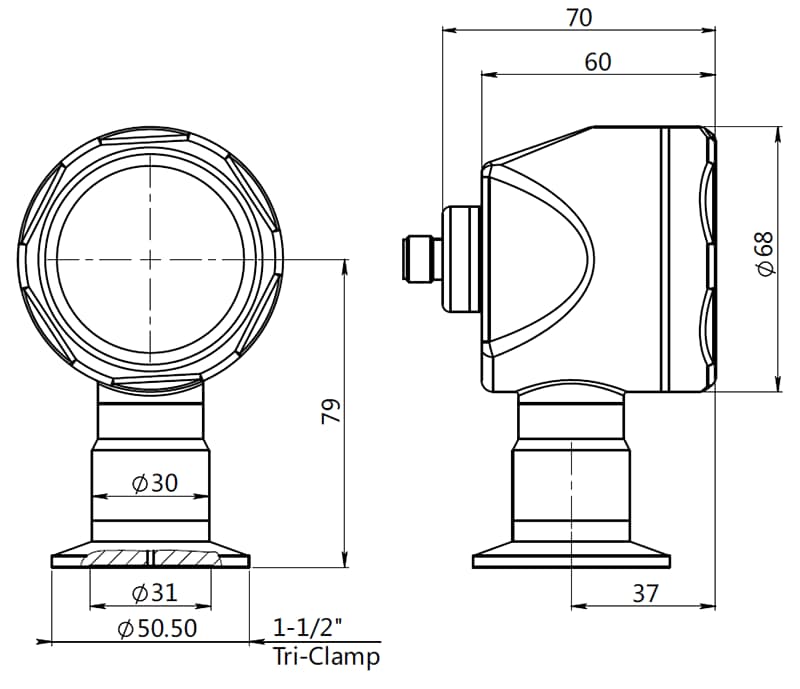

- Process Connection Type Tri-Clamp

- Process Temperature, Max 120 °C

- Process Temperature, Min -40 °C

- Storage Temperature, Max 85 °C

- Storage Temperature, Min -40 °C

Omega’s PX3005K02 is a compact, rangeable, digital sanitary pressure transmitter that is ideal for monitoring pressures in food and pharmaceutical industries where a flush diaphragm design is required. The rugged 316 stainless-steel enclosure is IP67 rated making it suitable for washdown environments. A 5-digit backlit LCD allows for full precision representation of process variable. This hygienic design has been issued 3-A symbol authorization and meets the requirements of the 3-A Sanitary Standards making it the best choice for process automation and tank level applications where consistent reliable pressure management are essential.

![]()

| Range Limits | |||||||||

| Nominal Value | Minimum Span | Upper (URL) | Lower (URL) | Over Range Limit | |||||

| kPa | PSI | kPa | PSI | kPa | PSI | kPa | PSI | kPa | PSI |

| 20 | 3 | 10 | 1.5 | 20 | 3 | -20 | -3 | 30 | 4.5 |

| 35 | 5 | 20 | 3 | 35 | 5 | -35 | -5 | 52.5 | 7.5 |

| 100 | 15 | 35 | 5 | 100 | 15 | VAC | VAC | 150 | 22 |

| 200 | 30 | 100 | 15 | 200 | 30 | VAC | VAC | 300 | 45 |

| 700 | 100 | 200 | 30 | 700 | 100 | VAC | VAC | 1050 | 150 |

| MPa | PSI | MPa | PSI | MPa | PSI | MPa | PSI | MPa | PSI |

| 1 | 150 | 0.5 | 75 | 1 | 150 | VAC | VAC | 1.5 | 220 |

| 1.7 | 250 | 1 | 150 | 1.7 | 250 | VAC | VAC | 2.55 | 370 |

| 3.5 | 500 | 1.7 | 250 | 3.5 | 500 | VAC | VAC | 5.25 | 750 |

Show Ratings & Reviews

Can the transducer be sent in for calibration?

Yes! This can be sent in for calibration to our Ohio Branch. I will need a part number, serial number, the type of calibration (compression/ tension/ system calibration), and your contact information and will then send you an estimate and a materials handling sheet to fill out. Feel free to send this information to cservice@omega.com and we will be happy to assist you with creating a return number. Thanks for your inquiry!

Date published: 2019-12-31