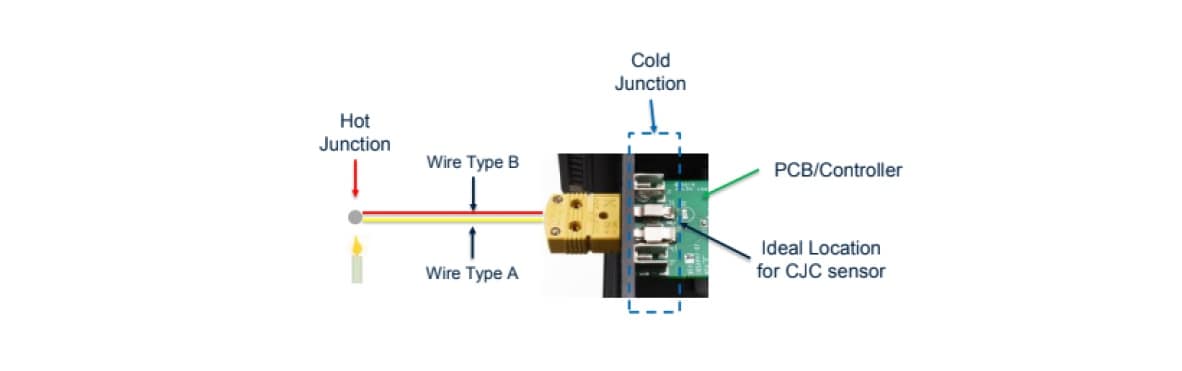

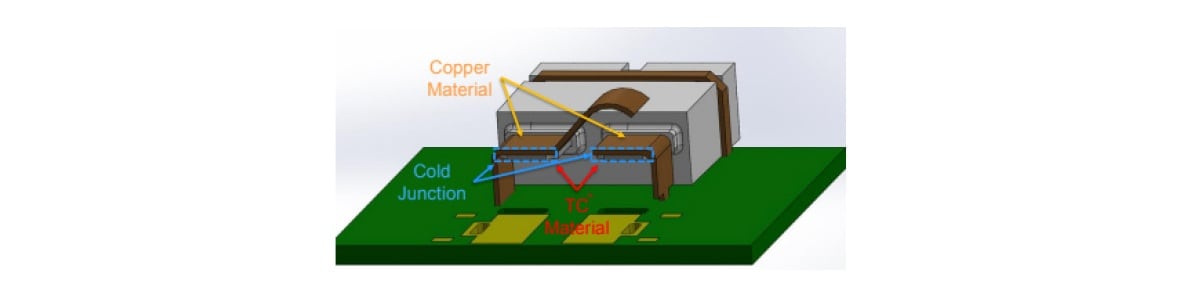

OMEGA’s new PCC-SMD unique features make integration of cold junction compensation easier than it ever has been before. It simplifies cold junction temperature measurement by allowing R&D designers to use industry-standardpick and place cold junction compensation elements (like SMT RTDs or SMT thermistors) and combine the cold junction compensation element with an analog-to-digital converter (ADC) to perform the final temperaturemeasurement.In a real application, using our PCC-SMD connectors, it would look like this:

These SMT populated connectors can be used with any thermocouple calibration and are designed for low-cost, high-volume production. They also feature a patent-pending asymmetric design that prevents connectors from being plugged in backwards.

Differences Between OMGEGA’s Legacy PCC-SMP vs. New PCC-SMP

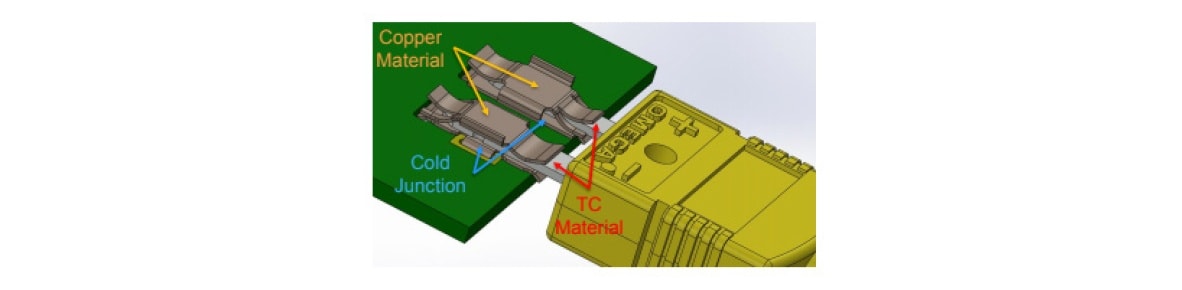

In our legacy PCC-SMP, the thermocouple calibration materials are inside the plastic housing, while copper pins, which are soldered to the PCB, are outside the plastic housing. The cold junction is located where the thermocouple calibration material welds to the copper pins. Thus, even with our legacy PCC-SMP/OST connectors, cold junction compensation is required.

New: PCC-SMD

New: PCC-SMD

Legacy: PCC-SMP/OST

Legacy: PCC-SMP/OST

The PCC-SMP-*-R also has a transistor retainer clip to accept TO-92 style transistor via manual placement and soldering, allowing cold junction compensation elements to bring the temperature measurement closer to the cold junction. However, with the new PCC-SMD, you can do this on the PCB with a surface mount technology (SMT) element instead.

By having the cold junction located where the connector meets the PCB, there is no need for compensated PCB connectors, which offers a significant value-add improvement, and makes it much easier to measure the cold junction temperature while also greatly reducing the labor cost associated with assembling the connector and required cold junction compensation.