Bienvenue sur notre nouveau site Web, vous avez rencontré un problème ou un bug? Veuillez le signaler ici

DPG-10M-Series

Pneumatic Parallel 2-Jaw Grippers, High Force

Modèles en stock

- Designed for Use in Applications Where Low Precision Positioning and Backlash Are Acceptable

- Excellent Choice for Diverter Gates, Escapements and Ejection Stations

- Multiple Body Mount Locations with Top and Bottom Mounting Using DIRECTCONNECT Robohand Technology

- Rotary Actuators Can Be Mounted and Operated in Any Orientation

DPG-10M-Series

Depuis

C$

1 074.59

Modèles en stock

L'aperçu du produit

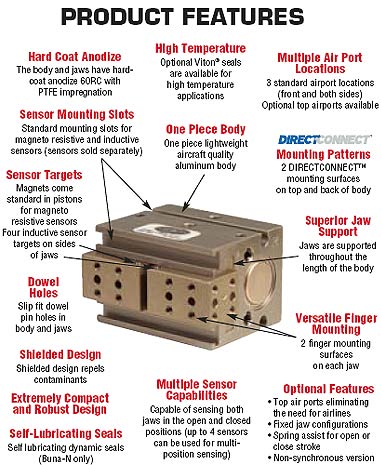

DPG Series Pneumatic Gripper is a parallel 2-jaw gripper with excellent parallelism and accuracy between the gripper mounting surface and jaw surface. Jaws can be mounted on the bottom or side and are supported throughout the length of the body to make this gripper an extremely robust, yet compact, design. They are also available with optional spring assist ("-C" option) on the close stroke to prevent the part from being dropped in case there is a loss of air pressure. They are available in stroke lengths from 6.4 to 25.4 mm (0.25" to 1.00") with a gripper force of 222 N (50 lbs). The DPG pneumatic gripper shielded design allows this gripper to be used in harsh environments.

DPG Series Pneumatic Gripper is a parallel 2-jaw gripper with excellent parallelism and accuracy between the gripper mounting surface and jaw surface. Jaws can be mounted on the bottom or side and are supported throughout the length of the body to make this gripper an extremely robust, yet compact, design. They are also available with optional spring assist ("-C" option) on the close stroke to prevent the part from being dropped in case there is a loss of air pressure. They are available in stroke lengths from 6.4 to 25.4 mm (0.25" to 1.00") with a gripper force of 222 N (50 lbs). The DPG pneumatic gripper shielded design allows this gripper to be used in harsh environments. The DPG pneumatic gripper is a modular component and can be mounted to DLT Linear slides or DRG Rotary Actuators without additional adaptor plates. They can be mounted on the top or side and have air ports on the top, side and front to support mounting and operation in any direction. Top manifold air ports can be used to help eliminate tubing and fittings at the gripper location. Accessory mounting slots make it easy to add magneto sensors and inductive sensor kits are available, the grippers have built in slots for inductive sensor targets.

Pneumatic linear motion automation components are double acting air cylinders that require a dry air supply with filtering to 40 microns or better. For best control of pneumatic components, flow control valves (regulating out) should be installed to regulate the speed of the device. Position sensors can easily be added to motion components to detect the end of travel positions of the slides, they are the standard method of communication with the PLC and are available in inductive or magneto resistive sensing styles and come in both PNP or NPN sourcing signals.