Bienvenue sur notre nouveau site Web, vous avez rencontré un problème ou un bug? Veuillez le signaler ici

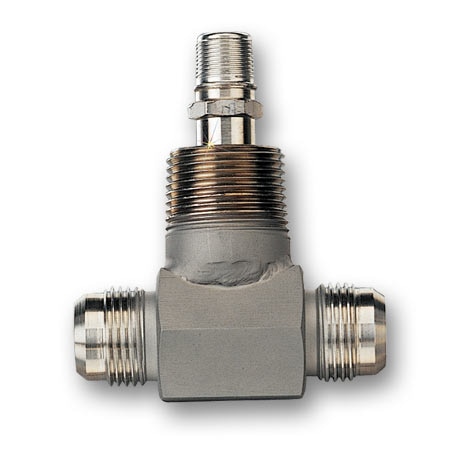

FTB200-Series

304 SS Turbine Flow Meters With 37 ° Flare Fittings

Modèles en stock

- ±0.5% of Reading Accuracy

- Ball Bearing Design for Economy

- Deflector Cones Stabilize Low Mass Rotor for Increased Bearing Life

- NIST Certificate for Water Included

FTB200-Series

Depuis

C$

3 194.89

Modèles en stock

L'aperçu du produit

- Accuracy ± 0.5 %

- Approvals RoHS, CE, UKCA

- Electrical Connection MIL-5015 10-4S

- Electrical Output Sinusoidal Wave

- Materials, Wetted 17-4 PH Stainless Steel, 304 Stainless Steel, 440C Stainless Steel

- Media Compatibility Liquids

- Operating Temperature, Max 232 °C

- Operating Temperature, Min -268 °C

- Output Signal DC Pulse

- Process Connection Type AN 37° Flare Male

- Repeatability ±0.1%

OMEGA™ FTB-201 Series turbine meters have male flared-end fittings for easy connections. They are built to meet the performance requirements of MS 33656, though they do not carry a military specification. These units come with a mating 2-wire connector and can be supplied with the integrally mounted signal conditioners to provide 4 to 20 mA, 0 to 5V, and factored pulse outputs.

Flow Straightening

Proper application of a turbine flowmeter requires that there be a suitable piping section both downstream and upstream of the meter if it is to achieve optimum accuracy. Whereas an inlet straight pipe run of 10 pipe diameters and an outlet straight pipe run of 5 pipe diameters provide the necessary flow conditioning in general, some applications require an upstream flow straightener. Such applications include custody transfer. A flow straightener consists of a section of piping which contains a suitably dimensioned and positioned thin walled tube cluster to eliminate fluid swirl. (see full specifications for "Typical Turbine Meter Installation Drawing".

37° Flare Installation Kits

Installation kits with the required up and downstream straight pipe lengths for proper turbine operation are available. Installation kits for turbine meters with 37° flare end fittings consist of two lengths of stainless steel tubing cut to a length appropriate for the upstream and downstream straight pipe runs and flared at one end. Mating sleeves and nuts are included. The kits can be conveniently butt-welded into the piping system. Flow straightening sections may be provided with the installation kit. Kits are available in tubing sizes from ½ to 2 ½".

Strainers and Filters

Turbine meters are intended for clean fluid service only; where there is any doubt concerning possible particulate impurities in the process fluid, strainers are recommended. A strainer/filter may be required to reduce the potential hazard of fourling or damage that can be caused by foreign matter. Pipe rouge, the extremely fine rust which develops on the inside of some piping, is a serious problem for turbine meters, due to the difficulty in filter out these particles. Consult Omega Flow Engineering Department for applications that may entail pipe rouge.

When using FTB-200 Series units for fluids with viscosities other than 1 centistoke, special calibrations and universal viscosity curves are available, consult OMEGA’s Flow Engineering Department for quote.

SPECIFICATIONS

Accuracy: ± 0.5% of reading

Repeatability: ± 0.1% of reading

Temperature Range: -268 to 232°C (-450 to 450°F)

Maximum Intermittent Overrange: 150% of maximum range

Materials of Construction:

Body: 304 SS;

Rotor: 17-4 PH SS

Bearings: 440C SS

Installation Kits: 340 SS, 1.7 mm (0.065") thick

Electrical: Two-wire connector, included

Max Pressure Drop: 0.34 bar (5 psi)

Flow Straightening

Proper application of a turbine flowmeter requires that there be a suitable piping section both downstream and upstream of the meter if it is to achieve optimum accuracy. Whereas an inlet straight pipe run of 10 pipe diameters and an outlet straight pipe run of 5 pipe diameters provide the necessary flow conditioning in general, some applications require an upstream flow straightener. Such applications include custody transfer. A flow straightener consists of a section of piping which contains a suitably dimensioned and positioned thin walled tube cluster to eliminate fluid swirl. (see full specifications for "Typical Turbine Meter Installation Drawing".

37° Flare Installation Kits

Installation kits with the required up and downstream straight pipe lengths for proper turbine operation are available. Installation kits for turbine meters with 37° flare end fittings consist of two lengths of stainless steel tubing cut to a length appropriate for the upstream and downstream straight pipe runs and flared at one end. Mating sleeves and nuts are included. The kits can be conveniently butt-welded into the piping system. Flow straightening sections may be provided with the installation kit. Kits are available in tubing sizes from ½ to 2 ½".

Strainers and Filters

Turbine meters are intended for clean fluid service only; where there is any doubt concerning possible particulate impurities in the process fluid, strainers are recommended. A strainer/filter may be required to reduce the potential hazard of fourling or damage that can be caused by foreign matter. Pipe rouge, the extremely fine rust which develops on the inside of some piping, is a serious problem for turbine meters, due to the difficulty in filter out these particles. Consult Omega Flow Engineering Department for applications that may entail pipe rouge.

When using FTB-200 Series units for fluids with viscosities other than 1 centistoke, special calibrations and universal viscosity curves are available, consult OMEGA’s Flow Engineering Department for quote.

| Meter Size | Mesh Size | Maximum Partical Size (in) |

|---|---|---|

| 1/4 to 1/2" | 100 | 0.0055 |

| 5/8 to 1 1/4" | 70 | 0.008 |

| 1 1/2 to 2 1/2" | 40 | 0.015 |

SPECIFICATIONS

Accuracy: ± 0.5% of reading

Repeatability: ± 0.1% of reading

Temperature Range: -268 to 232°C (-450 to 450°F)

Maximum Intermittent Overrange: 150% of maximum range

Materials of Construction:

Body: 304 SS;

Rotor: 17-4 PH SS

Bearings: 440C SS

Installation Kits: 340 SS, 1.7 mm (0.065") thick

Electrical: Two-wire connector, included

Max Pressure Drop: 0.34 bar (5 psi)

| Model No. | 37° Flare Fitting Size | Linear Range Water | Max Operating Pressure | Length | Nominal K-Factor pulses/gal | Weight kg (lb) |

|---|---|---|---|---|---|---|

| FTB-201 | 3/4-16 UNF-3A | 0.35 to 3.5 GPM | 5000 psi | 62 mm (2.45") | 13,000 | 0.4 kg (1 lb) |

| FTB-202 | 3/4-16 UNF-3A | 0.75 to 7.5 GPM | 5000 psi | 62 mm (2.45") | 10,000 | 0.4 kg (1 lb) |

| FTB-203 | 3/4-16 UNF-3A | 1.25 to 9.5 GPM | 5000 psi | 62 mm (2.45") | 6,000 | 0.4 kg (1 lb) |

| FTB-204 | 7/8-14 UNF-3A | 1.75 to 16 GPM | 5000 psi | 70 mm (2.75") | 4,100 | 0.4 kg (1 lb) |

| FTB-205 | 1-1/16-12 UNF-3A | 2.5 to 29 GPM | 5000 psi | 83 mm (3.25") | 2,200 | 0.4 kg (1 lb) |

| FTB-206 | 1-15/16-12 UNF-3A | 4 to 60 GPM | 3500 psi | 89 mm (3.50") | 640 | 0.9 kg (2 lb) |

| FTB-207 | 1-5/8-12 UNF-3A | 6 to 93 GPM | 3000 psi | 99 mm (3.88") | 410 | 0.9 kg (2 lb) |

| FTB-208 | 1-7/8-12 UNF-3A | 8 to 130 GPM | 2250 psi | 111 mm (4.38") | 230 | 1.4 kg (3 lb) |

| FTB-209 | 2-1/2-12 UNF-3A | 15 to 225 GPM | 1750 psi | 121 mm (4.75") | 120 | 1.8 kg (4 lb) |

PDF et manuels

Afficher les notes et les avis

Does this work with two-phase flow?

Thank you for your inquiry! Unfortunately, these units are only suitable for single phase flow

Date published: 2022-10-13