1-800-663-4209 | Your feedback matters, take a quick survey Website Feedback

Snap-fittings

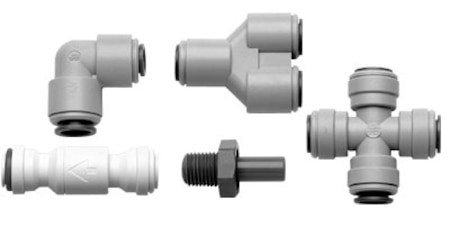

“SNAP-IN” FITTINGS FOR FLEXIBLE AND COPPER TUBING

Models In Stock

- 100%Leakproof Installations, EveryTime

- Efficient, Rapid Connections, Even in Tight Working Quarters

- Reductions in Maintenance Cost

- Suitable for Plastic and Copper Tubing Applications (For Stainless Steel Applications Consult Factory)

Snap-fittings

From

C$

40.17

Models In Stock

Product Overview

- Air Temperature, Max 75 °C

- Air Temperature, Min -25 °C

- Diameter 0 in

- Materials Acetal, Nitrile Rubber, Stainless Steel

- Operating Pressure, Max 150 psi

- Water Temperature, Max 60 °C

- Water Temperature, Min 1 °C

OMEGA Connectors for use in, Food Service, Research and Industrial, Laboratories, Fluid Applications, Compressed Air, Plastic and Copper, Tubing Applications

OMEGA fittings and color coded caps are manufactured using food grade Acetal Copolymers and stainless steel - Our O-rings are produced from food grade Nitrile rubber. OMEGA fittings meet stringent ISO 9001 requirements and exceed all specifications implemented by the FDA, NSF and Water Quality Association. Together, and in combination with patented, proprietary design, your customer’s health and safety are never compromised.

Application Adaptability

Our fittings are modular in design, they can be coupled together to form new integral fittings, making any complex connection requirement fast and simple.

Easy, Quick Installation

Contrasting the time consuming procedure of sweating traditional copper connections, the installation of OMEGA fittings is a click and a snap. There is no need to drain systems, remake leaky solder joints, or adjust awkward compression fittings—an especially important feature when working in confined spaces. Typical installation times can be cut by as much as 40%. Despite this drastic cut in installation time, tests show that OMEGA fittings have a substantial service life of 20 years, while withstanding temperatures and pressures well in excess of normal working situations.

OMEGA fittings and color coded caps are manufactured using food grade Acetal Copolymers and stainless steel - Our O-rings are produced from food grade Nitrile rubber. OMEGA fittings meet stringent ISO 9001 requirements and exceed all specifications implemented by the FDA, NSF and Water Quality Association. Together, and in combination with patented, proprietary design, your customer’s health and safety are never compromised.

Application Adaptability

Our fittings are modular in design, they can be coupled together to form new integral fittings, making any complex connection requirement fast and simple.

Easy, Quick Installation

Contrasting the time consuming procedure of sweating traditional copper connections, the installation of OMEGA fittings is a click and a snap. There is no need to drain systems, remake leaky solder joints, or adjust awkward compression fittings—an especially important feature when working in confined spaces. Typical installation times can be cut by as much as 40%. Despite this drastic cut in installation time, tests show that OMEGA fittings have a substantial service life of 20 years, while withstanding temperatures and pressures well in excess of normal working situations.

PDFs & Manuals

Show Ratings & Reviews